Mobile Plant 40 TPH:

- Capacity 20 – 40 TPH

- RAP Percentage (3% humidity) 50% – 70%

- Cold & RAP Silo , Equipped by Mesh and Vibrator

- Cold silo with capability of loading from both side

- Standard portable steel chassis

- RAP & Aggregate Feeder with speed control

- Insulated single drum furnace with special and innovative design

- High heat efficiency and temperature controlled furnace

- Burner using diesel fuel

- Equipped by special drag conveyor for loading recycled asphalt

- Ability of loading truck

- User friendly computer control & monitoring system

- Special control cabin

- Rejuvenator tank with all facilities

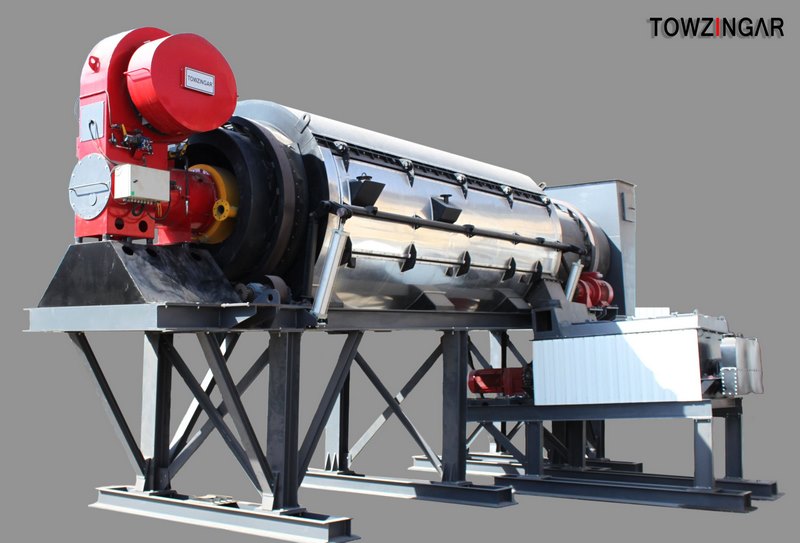

Mobile Plant 80 TPH:

- Capacity 40 – 80 TPH

- RAP Percentage (3% humidity) up to 50%

- Standard multi axles portable steel chassis

- Well insulated continuous double drum furnace with special and innovative design

- High heat efficiency furnace and continuous temperature controlled

- Fully controlled Burner (dual fuel optional )

- Equipped by high speed discharge system

- Smart control & monitoring system of key parameters

- User friendly monitoring system

- Programmable computer control system (PLC)

- Automatic and manual control (dual control)

- Special control cabin

- Equipped with external secondary mixer

- Emission control using high efficiency bag filter

- Facilitate to recirculating system of bag filter filler

- Equipped by aggregate and RAP sampling system

Mobile Modules:

Potable RAP crusher and screen module

- A cold silo with mesh and vibrator

- Continuous feeder of RAP to feed screen

- Multi-level screen for grading of RAP to different mesh size

- RAP crusher made of hardened material

- Standard multi axles portable steel chassis

- Easy in installation and disassembling

Note : RAP crusher can be delivered in the form of stationary

Potable cold & RAP silos and feeders module

- Cold & RAP multi silos , equipped by mesh

- Covering the mesh sizes of aggregate material

- High accuracy feeder with drive speed control

- accurate continuous weight measurement

- Standard multi axles portable steel chassis

- Easy in installation and disassembling

Note : Cold & RAP silos can be delivered in the form of stationary

Potable bitumen & additives heating and storage tanks module

- Portable well insulated bitumen flask with heating coils

- Oil Heater for supplying high temperature oil

- Modified Bitumen system with mixing tank and reserve tank

- Module equipped by accurate metering system for bitumen & additives

- Portable Module covered and insulated well

- Easy connectable to recycled asphalt modules

- Standard multi axles portable steel chassis

- Easy in installation and disassembling

Note : bitumen & additives heating and storage tanks can be delivered in the form of stationary

Potable hot asphalt conveyor, storage silo module

- Adjustable drag conveyor for delivering asphalt to storage silo

- Powered hydraulic actuators for adjusting drag conveyor

- Drag conveyor used anti-abrasion steel in body

- Storage silo well insulated against heat loss

- Standard multi axles portable steel chassis

- Easy in installation and disassembling

Note : hot asphalt conveyor, storage silo can be delivered in the form of stationary

Stationary 200 TPH:

- Capacity 80-200 TPH

- RAP Percentage (3% humidity) up to 50%

- Stationary System

- Well insulated continuous double drum furnace with special and innovative design

- High heat efficiency furnace and continuous temperature controlled

- Fully controlled burner (dual fuel optional )

- Equipped by high speed discharge system

- Smart control & monitoring system of key parameters

- User friendly monitoring system

- Programmable computer control system (PLC)

- Automatic and manual control (dual control)

- Special control cabin

- Equipped with external secondary mixer

- Emission control using high efficiency bag filter

- Facilitate to filler recirculating system of bag filter

- Equipped by aggregate and RAP sampling system

- Oil Heater with high capacity for heating oil

- Multi Cold silos , equipped by mesh and vibrator

- Multi RAP silos , equipped by mesh and vibrator

- Special control cabin

- Insulated bitumen flasks heated with internal coils

- Rejuvenator and mixing tanks with related equipment

- Modified Bitumen plant with mixing tank and reserve tank

- Insulated storage silos with high capacity